Steel

Drive Energy Efficiency and Excel in Production

Improve energy efficiency in steel production by minimizing waste, optimizing processes, and reducing costs to support sustainable growth and operational excellence.

Platform Capabilities

Streamlining Resource Utilization

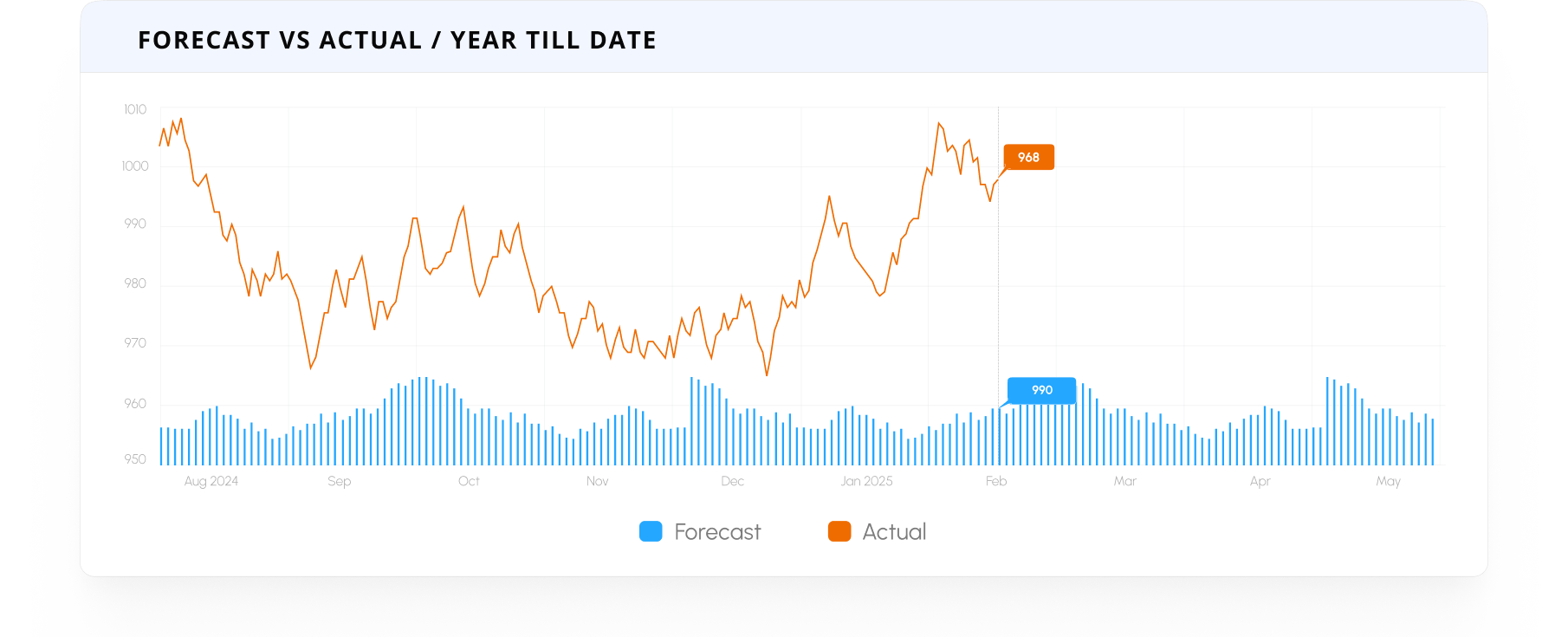

Demand Forecasting

Optimize captive power generation and grid connectivity by forecasting energy demand, ensuring cost-effective and uninterrupted steel production.

Energy Accounting

Track and optimize energy consumption across furnaces, rolling mills, Continuous Casting Machines (CCM), and Direct Reduced Iron (DRI) processes for maximum efficiency and cost control.

Prescriptive Maintainance

Optimize maintenance scheduling across furnaces, re-rolling motors, hot rolling, and cold rolling processes to prevent downtime and enhance operational efficiency.

Pattern Recognition

Detect inefficiencies in furnaces, reheating furnaces, and CCM by analyzing energy consumption patterns, enabling proactive adjustments for improved performance and cost savings.

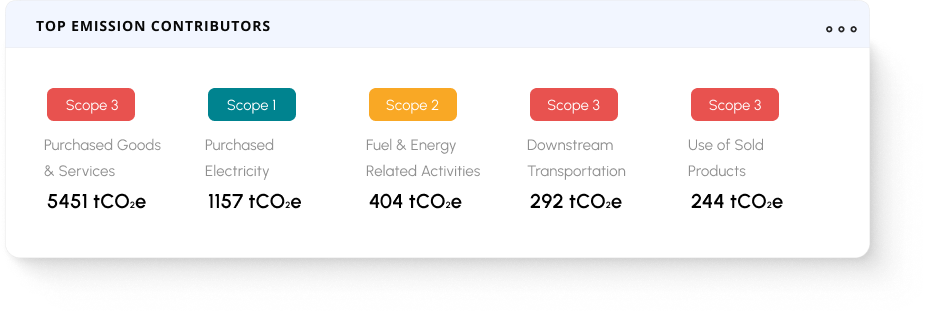

Carbon Footprint Analysis

Track and reduce emissions from energy sources, production, and logistics, aligning with green steel manufacturing while maintaining operational efficiency.

Trusted By

Solutions

AI-Powered Insights for Sustainable Growth

Energy

Balance

Identify and implement specific energy-saving actions, cutting costs and balancing usage.

Water

Balance

Target and reduce excess usage for cost-effective, sustainable water practices.

Asset Lifecycle

optimization

Drive significant cost savings and optimize asset performance throughout their lifecycle.

Net Zero Transition

Program

Fast-track to net zero with actionable insights and complete emissions visibility.

Enterprise Data

Intelligence

Integrate our data into your systems, BI platforms, and custom models via a robust interface.